-

Content Count

1,160 -

Joined

-

Last visited

Content Type

Profiles

Forums

Calendar

Posts posted by ChrisR-4A

-

-

1 hour ago, Waldi said:

Hi Roy,

The TR6 aluminium covers often lack the baffle to reduce oil loss, not sure if this also applies for the 4-cyl covers.

Also, I would like the machined groove for a (silicone) O-ring gasket.

If you decide for rechroming, make sure your cover is straight.

Regards,

Waldi

+1 for the machined groove to take the O ring, best aid to easier servicing since the spin on filter. No more messing about evo sticking cork gaskets on only to have them fail when you have an emergency.

Chris

-

Hi Don, the cut off green wire probably ran to an override switch which would be connected to earth so when switched on it would provide earth to the fan same as probe does. I prefer a manual override switch because it allows you to quickly test the fan motor is working and also allows you to preempt the theroswitch when you can see the temp is about to climb, like at start of a long strep hill or a traffic jam. It is also easy to wire a fan on warning light to the override switch. Simply connect a warning light with a ign on live feed and let the override switch provide the earth when on. This will allow the warning light to come on whenever the fan is on, whether by theroswitch or manual, and only one additional single wire is needed from the relay to the override switch.

Chris

-

Hi Alan, firstly check how hard the underseal is and whether there are any cracks in it, cracks could mean moisture has got in, either way I would remove just a sample first to see how well it has adhered. Then it depends what you want from the car, recommissioning suggests you would like to use it soon so I wouldn’t start taking it all apart unless it’s really necessary otherwise you could be into a protracted rebuild.

Chris

-

Southend Airport back in the day. (1963) I went on one of those Carvairs In the early 70s to France with a work colleague in his MK1 Ford Capri, it was a metallic bronze colour.

The video below is the Carvair but there's an on screen link at the end to a video featuring the Bristol Freighter, early sixties with two doors.

-

Hi Ross, where did you get the new clutch from, it could be the clutch plate splines. Also check the bush is still in the crankshaft which supports the input shaft.

Chris

-

Hi Jean-Marie, the points plate rotates a small amount on the baseplate to allow the points to be set so if you dismantle both items you should only have to reset the points gap, that’s assuming the two baseplates were identical.

It is possible to have two baseplates, I have one with an electronic ignition module fitted to it and a spare ( in the boot) fitted with points and condenser with the points gap preset which can be fitted to the car if the electronic unit fails. By swapping the assembly, undoing the two Phillips screws and lifting it off the A/R spring the points are a direct swap and no adjustment is req for the engine to run. Having said that it’s always worth checking the timing after changing anything. I have had to do this so I know it works.Chris

-

No Mick, it was on the car when I bought it, I was told by a PO that it was a new wing fitted in 1979 and that it was meant for a TR5 as that's all that was a avail back then. It also doesn't have the shelf for the horn which is why both my horns are on the LH side.

So far I've only tested it in garage for air flow by placing a large household fan in front of the car. The new pipe does direct the airflow fairly evenly to the underside of both air filters. What I did notice was that no noticeable airflow was entering the underbonnet space from anywhere else so without the new inlet most of the underbonnet air must be that coming through the rad, which is obviously at higher temp than ambient.

Chris

-

11 hours ago, ed_h said:

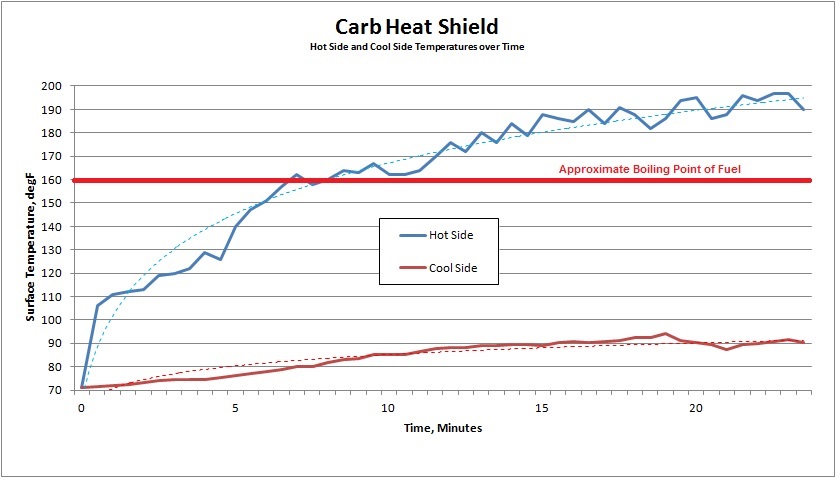

That looks good Ed. It’s what I expected a heat shield to look like, not the vertical one sold by Moss.

Just need to make one for my 4A now and find a neat way of attaching it like you have.Chris

-

37 minutes ago, Steves_TR6 said:

That was me !

i installed a sensor in the plenum and whilst driving along the air temp was indeed close to ambient

but when ticking over in traffic the air temp went above 80c

my pi car has the standard air filter arrangement , but with a k&n filter, which sucks cold air from in front of the rad.

steve

Hi Steve, I can understand from this discussion that the needs of an injected 6 are different from an engine on carbs with under bonnet air filters . The injected 6 at all times draws its air from outside the bonnet area but is affected when stationary by under bonnet heat being transferred to the plenum which will increase the air temp inside.

Whereas the engine on carbs is drawing its air from the under bonnet area at all times so will not have the same benefit of the injected car when moving; therefore an additional cold air feed to the under bonnet area around the air filters looks like it should be beneficial, more so as the road speed increases.Chris

-

I think you are right Peter as some cars have been known to suffer from fuel starvation causing difficult hot starting, Marcel’s solution is practical but a detailed sheet of alloy with some judicial forming would look better and if stood off from the underside of the manifold on short pillars should be more efficient. Really need a spare manifold off the car to do this, I’ll put it on my “One Day” list.

Chris

-

3 hours ago, Peter Cobbold said:

Maybe, But a simple ali plate between the manifolds will reflect almost all the radiant heat. Convected heat should be blown away by underbonnet air flow, and conduction is fixed by the manifold/ head bolts.

Peter, the heat shields shown in the Moss catalogue appear to be vertical and fitted between the carbs and the inlet manifolds will stop exhaust heat reaching the carbs but not from rising vertically onto the inlet manifold. Is this good enough or is something else needed to do a "propper job".

Chris

-

4 hours ago, ed_h said:

There was a thread on one of the forums a while back where someone installed temperature sensors at various places under the bonnet. One revelation was that, at road speed, underbonnet air temps were essentially the same as ambient.

Ed

I could accept that but only if there was ample venting between the engine bay and the front of the car. My gut feeling is that on a TR there isn’t as standard. Which is why I have added an extra inlet to feed air around the carbs. I can also see Peters point on a heat shield between the exhaust and the inlet and will be looking into this as well.

Chris

-

Hi Mike, I see your in Melbourne where summer temps are similar to a good U.K summer. I’m not expecting to notice too much difference in U.K. except on warmest days but each year when we go to France in July temps are often 29-35 deg and colder under bonnet air should be welcome .

I assume both you guys have the standard TR6 injection, the benefits of colder air would be more noticeable on a 6 with carbs and K&N filters more so with triple Webber’s.

Chris

-

Hi Stuart, I have just added a cold air intake to the 4A, do you have the flexible hoses to the inlets on your air box , these could be routed to an area open to cold air from the front of the car. As they feed the air box before the filter this should not introduce any pressure into the inlet which would adversely affect the mixture.

Chris

-

Good point Roger that's why I wondered if anyone on forum had fitted one.

Chris

-

Stuart, is your rad cap just a plain cap with no spring and is the one on the expansion tank the one that was on the rad, 7 psi ?

Chris

-

-

Most engine builders just plug the hole, for draining water it's easier to remove bottom rad hose. If engine has been rebuilt recently plug is good for prob 10years.

Chris

-

+1 for Stuart’s comments .

My rad overflow pipe had been rubbing the paint off the edge of the bonnet reinforcing cross member for years. In the process of recently tidying up the whole of the front under bonnet area and moving the overflow bottle to the LH side to allow a cold air inlet on the right I checked the rad height and found that the rubber spacers under the bottom mounts (fitted by me many years ago) were nearly 8mm thick. I replaced these with 1.5mm rubber washers and the hose now just clears by less than 3mm checked with 2 bits of masking tape and a dab of paint. Note the hose outlet on my rad has always pionted to the left.

Chris

-

I guess one answer is the same as when an enthusiastic dog owner was asked why the mutt was licking his nether regions replied, "I suppose it's because he can"

On a more practical note for us mere mortals is not to be put off Servicing our modern Euroboxes. There are exceptions but many new cars are as easy to Service as the old TR.

For example my A3 has an easily accessible spin on oil filter and sump plug. For nearly £200 all my main dealer would do is change the oil and filter and run through a check list.

Any additional needs would show up on the dashboard display like brake fluid change and after 40,000 miles new plugs. Easy money for just over an hour's work.

Chris

-

Hi Andy, if the grey smoke is anything to do with Petrol then I would check the spark plugs first and try a new set. There have been a lot of complaints about NGK plugs recently and I have just binned one from my 4A for causing an erratic tickover. If that does not resolve the issue then just to rule it out I would try removing the electronic ignition and reverting to points. Whatever you decide to do only change one thing at a time and then retest, otherwise you won't be sure which change fixed the problem.

Chris

-

Hi Buck, firstly can I say I admire you dexterity regarding your loss, or was it the young ladies?

Secondly I have been using the same Magnatronic ignition unit for over 8 years with no need for any readjustment. However I do carry a spare distributor top plate with points and condenser fitted in the spares box just in case.

Chris

-

1 hour ago, Waldi said:

Too large diameter inner tubes will also give issues.

I fail to understand why people use duct tape for this.

Waldi

+1

for oversized tubes, many tyre shops only carry a limited stock of tube sizes as hardly any vehicles use tubes today and if faced with finishing a repair will fit what they have in the correct diameter which may be far too wide resulting in folding, friction and a blowout.

I had to stop my local shop doing exactly that and then waited 24 hrs for delivery of correct size tubes.

Chris

-

1 hour ago, stuart said:

Standard discs are fine for all road use and last a lot longer than the fancy slotted/drilled, forget the Green stuff pads as they give a "Wooden" feel to the pedal and dont work that well at all, I like the Hawk pads but they are quite expensive.

Stuart.

+1 for Hawke Pads.

I fitted drilled and slotted discs a few years ago and with standard pads and a Servo they were far from impressive. However last Jan I fitted the Hawke pads and there is a marked improvement, good bite in slow traffic and at speed they have more stopping power and the car remains in a straight line.

If I was starting from scratch I would fit the Hawke pads first, then if not good enough a Servo and then maybe the slotted/drilled discs.

The Hawke pads do have the 1/4 pin holes but fit straight on a 1965 TR4A. Easy enough to drill out the calipers if req there a loose fit anyway.

Chris

My first TR

in General TR Technical

Posted

Hi Chris, great looking car, on a recently rebuilt car there’s a lot of settling and some retightening of fixings may be necessary. It’s worth checking the exhaust has not dropped where it goes through the chassis breastplate at rear and also the mounting bolts for the lever arm shock absorbers to the chassis bridge. These need to be very tight to avoid movement.

Chris