-

Content Count

7 -

Joined

-

Last visited

Content Type

Profiles

Forums

Calendar

Posts posted by Britcarfan

-

-

So that's it then - nothing happening until April, just assumed it was a rolling 40th anniversary of the registration date. Tax paid now - £165, might get a refund if or when one 's due.

Thanks guys for your help & comments, Dave.

-

Not sure if I've posted this in the correct place but here goes.....

September 2020 - DISASTER!! - 'covid 19' or just incompetance?

My Spitfire 1500, registered 1st August 1980 should now be tax & test exempt. I received my tax reminder about three weeks before hand, and went to the post office to do the biz. She scanned the bar code on the V5c and said that it's not yet listed as tax / test free so come back just after the 1st of August. I went in again about 8th August and she said the same thing, all assuming that there's probably no-one currently home at DVLA, and suggested I send the V5c to DVLA myself (?!) which I did + form V112, and proof of posting.

I returned to the post office on 4th September, this time with a copy of the V5c, only to be palmed off again with same answer, so I took screen grabs of DVLA's web pages showing the vehicle's tax status (not taxed) + instructions to take it all to the post office, as I had done - all to no avail.

I am now totally stuffed, the car's MOT'd and insured but I'm unable to tax it. If I get pulled over I risk a heavy fine or even loosing the car.

So - is it the present situation or is she just bloody useless at her job?

Has anyone else had a similar experience, or did it all go ok (post 20th March 2020)?

HELP!!!,

Dave

-

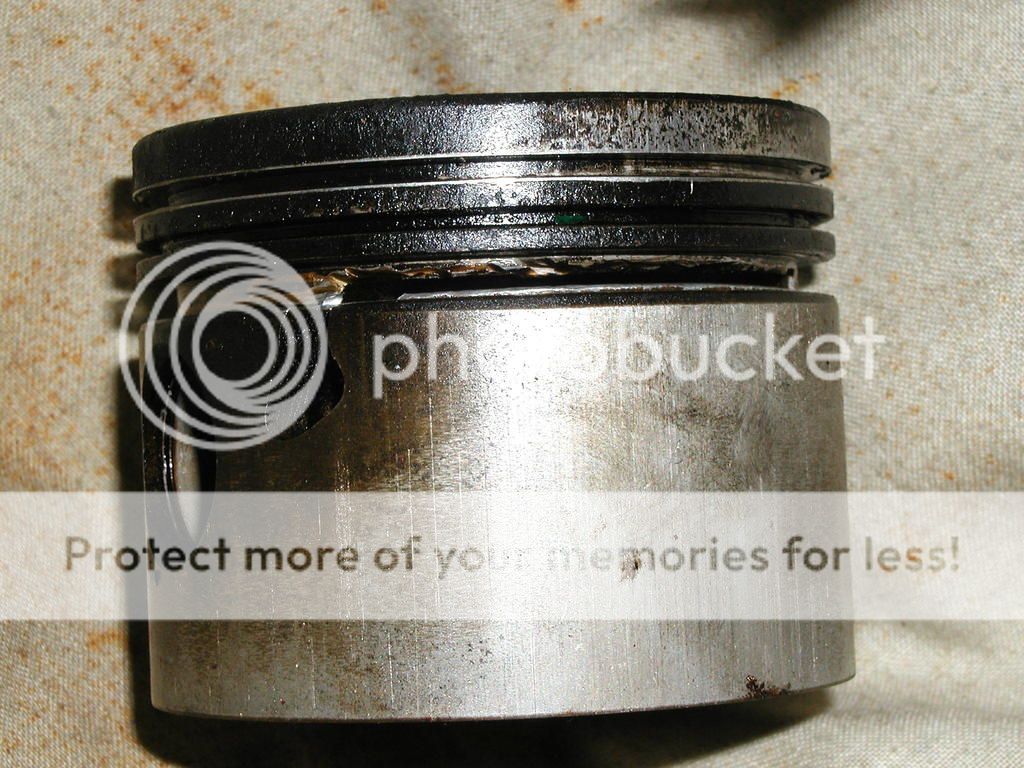

The gentleman assured me this engine had not seized!!

(yeah right!). On investigation I found that one of the core plugs on the front end - the one inside the timing cover had rusted through, dumping the entire water supply into the oil, so the engine was 'lubricated' by an emulsion of oil, water and very gritty rust. The oil pump represented a ploughed field, and in the sump along with the bits of rings were flakes of rust! Yummy.

(yeah right!). On investigation I found that one of the core plugs on the front end - the one inside the timing cover had rusted through, dumping the entire water supply into the oil, so the engine was 'lubricated' by an emulsion of oil, water and very gritty rust. The oil pump represented a ploughed field, and in the sump along with the bits of rings were flakes of rust! Yummy. -

-

Hi Roger,

I was watching some YouTube videos the other day to do with checking conrods. In both cases the bolts were fully torqued up to test for twist & bend - Does this mean that the bolts are then scrap? - ok I suppose if money's no object and the customer's paying....

I've no experience with TR 4A bolts and have never seen them so am unable to comment. Perhaps some 4A owners may have an opinion. If the originals were definitely stated as one use only, perhaps best to play safe.

Dave

-

Interesting thread. I'm pondering this one as well as I'll be building a 6 up soon.

I'd like to use new, but frankly I don't trust the new "standard" stuff available today to match OEM quality.

The route used to be to use Sierra Cosworth bolts - unfortunately NLA. You could hock a kidney and get some ARP ones but it is worth considering that the bolts screw into threads in the conrod, which you can't do anything about, and it is frequently these that let go first.... especially where fancy, extra-strong bolts have been torqued up tighter than standard.

The standard ones are not stretch bolts as such. It is true that they will stretch when tightened, and it's this that keeps them done up, but they should return to their original length when released, provided they've not been overtorqued. True stretch bolts, as used on many modern cars will be torqued and further tightened through a specified angle. These will be permanently stretched and are one-time use only.

Not all of the 4 cylinder Triumph engines use locking tabs. All but the earliest 1200,1300 and 1500 use the same arrangement as the 6. I've re-used the big end bolts on those several times, including an engine that was regularly revved to 7,000 rpm and got away with it - blind luck maybe.

I couldn't agree more -

To me the bolts used in my 1500 engine do not look like they were neant to permanently stretch. When an engineer designs an item such as a stretch bolt he needs to control exactly where the stretch is going to take place, the bolt being necked down in that area smaller than the thread. This not the case with either the big end nor the main bearing bolts. The stems of the big end bolts are equal to the minor diameter of the thread, so if it were to stretch it would equally stretch in the threaded area, destroying the female thread. In the case of the main bearing bolts the stem is actually equal to the MAJOR diameter of the thread! so the thread in the block would strip before the bolt even thought of stretching.

My experiences with after-market parts have left me with little confidence in them. The original bolts were made by Guest Keene & Nettlefolds from a specific high tensile steel to a British spec and given a specific heat treatment. I've currently got my Spitfire 1500 engine stripped down and have examined and measured every big end & main bolt - Firstly the mains: the BL manual has the length wrong at 3" - they actually measure 2 7/8" (unless they've shrunk) and I can see no evidence of plastic (permanent) deformation. The big end bolts are given as 1.65" but all come out about 15 thou less than that, so perhaps they were meant to be 1 5/8" with an elgation of 10 or 12 thou, which I would be more inclined to put down to 'creep', where a material changes shape as a result of long term stress (eg sagging car springs).

Anyone who did a tensile test in college (our test piece was copper) will know that most metals will stretch in a linear manor within thier 'elastic limit' - within this range if the load is relaxed the specimen will return to its original length. Eventually the test piece will reach its elastic limit, with a sudden increase in length for no increase in load. At this point the material has necked visibly in one place and this area work hardens. The graph of stress over strain then continues to rise a short way until the piece fails with a resounding bang.

Thus for permanent deformation to occur the steel must exceed its elastic limit, as with the modern stretch bolts which are visibly designed to stretch.

Perhaps there's a metal fatigue or microscopic cracking issue but I wouldn't have thought so given that the stress in one direction only.

Having said all that, the BL manual suggests changing the big end bolts but I can't understand why, and there is no mention of the main bearing bolts.

As rule classic cars don't do many miles and unless they're high performance engines, thier owners are unlikely to over rev' or cane them.

Unless the engine refurbisher can convince me otherwise I'll be refitting the originals - a known quantity.

Disclaimer - the above are just my own opinions and obervations. Whether or not you change the bolts is your choice and your responsibility.

Problems registering tax & test exempt

in Social Scene

Posted

Thanks wjgco,

Just the info I needed, I've saved the PDF for 'er at the post office in case I should need it come April. Not sure what the green book is, is it a record what rolled off the production line? - fascinated!

Dave