hoffman900

-

Content Count

78 -

Joined

-

Last visited

Content Type

Profiles

Forums

Calendar

Posts posted by hoffman900

-

-

On 8/8/2023 at 7:43 AM, Kenrow said:

Is this so? If yes it is interesting bit of information. As noted, the whole discussion is mute if you use the same manufacture for the cam and followers.

It would suppose to be, but due to manufacturing machining errors, likely isn’t.

You can measure this when building. Find TDC for each cylinder (will show crank twist), and then record cam timing for each cylinder. You’ll likely find variance beyond measurement error.

-

“Lively”

And unnecessarily so!

-

3 hours ago, BlueTR3A-5EKT said:

Is this the same issue that Tesla have?

Follow one and note the bouncy, bouncy, bouncy, travel sick look from rear seat passengers scenario.No that just sounds like bad shock tuning.

-

Peter Wright also with the explanation:

-

6 hours ago, john.r.davies said:

Famously, Adrian Newey doesn't NEED a tunnel - he can SEE the wind!

My paper this morning quotes George Russell as saying he had just the same problem as Hamilton with his car, and that with the best of luck they don't hope to be competitive towards the front for "eight or nine races"! How ironic, that another 'boy genius', and new British hope, arrives at Mercedes just they drop the biggest clunker onto the circuit!

John

They had a different set up. It’s documented everywhere.

Adrian Newey absolutely needs a wind tunnel and cfd. Also, I always think it’s a bit disingenuous he gets all the credit when he is dealing with nearly 1000 engineers across RB and their suppliers.

-

19 minutes ago, john.r.davies said:

Thanks for the image!

A lot of people give Adrian Newey credit on RB’s side right now, but he was only 23yo when they got rid of tunnels in F1 and he was in Indy Car until 1985. Tunnels were used there but the tools were really rudimentary.

I think from the chassis side of things, RB’s technical partnership Multimatic helps a lot, especially with their CART/Indy and WEC/IMSA experience. Obviously, it still stems from an aero issue.

I found a post from a former F1 aerodynamicist some years ago talking about Karman Vortex induced oscillations in regards to the front wing, but they got away with it because as a % of total downforce, it got canceled out. Not so now if the issue is with the floor.

fyi: for those that don’t know, these forces are what cause skyscrapers to go into resonance and need a tuned mass damper at the top.

-

28 minutes ago, Motorsport Mickey said:

I think they'll revert to setting Hammy up with Georges settings Hoffy.

When Hammy used to partner with Jenson Button Hammy would drive the wheels off the car and come in with fastest time and say "leave the car it's ok" whereas Button on the same set up would come in from his session with a slower time and say "understeer turn 3, 5 and 7 and oversteer on 9 with the cars balance changing as the session went on becoming looser...change it". Sure enough setting the same settings as Buttons on Hammy's car gave even better pace, which Hammy delivered on. I don't believe he's the most technical as regards what he drives...he just gets the best time out of whatever he's sat in !

Mick Richards

That was a long time ago now (a decade ago). I think George is willing to go with whatever the engineers give him at this point where Lewis, as he has gotten older, is more of an Alain Prost type, and seems to have a lot more input into the setup.

It did work better on hard tires later in the race, with Lewis running the same times as George on 20-some lap old hards to George’s fresh mediums. The problem is they are setting up around this porpoising issue, so a lot of what they are learning now won’t hold true when/if they get the car working.

-

On 3/27/2022 at 3:22 AM, RogerH said:

Hi Folks,

what has caused the Mercedes/Hamilton downfall this season.?

How can all the other teams improve so much and Merc go backwards?

Roger

Correlation issues.

There has been much talk about what causes porpoising. The F1 media talking heads attribute it to the air stalling, by a PhD Aerodynamicist I am friends with said on day 1 at Barcelona is that is caused by vortex shedding (Karman Vortex street) inducing resonance into the chassis and aligning with the frequency of the suspension to cause it. Jean-Claude Migeot was the only talking head to comment on this, and James Allison later said as much when he said the F1 media-sphere was incorrect.

The problem is these things cannot be seen in CFD. CFD does not handle turbulence well and the models are assumed to be infinitely stiff (too hard and not enough computing power). Furthermore, the wind tunnel models are 60%, no to minimal suspension (and won't resonate the same), and are speed restricted. They were only going to find this in real cars on real race tracks.

Lewis's problem this weekend was wrong direction in set-up and different than George. Simple as that. Until they get new parts, they are throwing hail mary set ups at the car.

-

On 10/31/2021 at 7:39 AM, MichaelH said:

Hoffman's 175 ft Lbs of torque at the back wheels of a 4 cylinder TR4 in a race engine. In that case his race engine must have better flow and more CCs and better fuel and higher compression.

I would appreciate where his engines are significantly better so that I can adopt his methods. Any help is good and I can always learn !

Oh and if I could drive well That would help!

Michael

I don’t build engines and am busy with another project.

It would likely be the same or more expensive. More expensive because you are stuck with stock rocker arms, so you’re going to have to go with proprietary lobe designs and cam core to get the lift you need, vs being able to likely use an off the shelf lobe design (say from an older NASCAR application).

Everything else is all going to be custom anyway. Less compression isn’t always a bad thing. Anything with more than a flat top is a compromise in terms of combustion efficiency… does the increase compression offset compression efficiency losses? Especially when you start adding in valve reliefs, etc. It’s a slippery slope.

The best A-Series cylinder head porter here is getting 130cfm sq-in through the throat at 28” H2O on the bench. A TR3-4 head would be around 215cfm using that figure, and no reason it shouldn’t with the right development / person doing it. That value alone will support over 100hp/L with everything else being developed to the same extent.

-

2 hours ago, ntc said:

I have always said the true figure is only on a engine dyno and I challenge anybody to show me the same figures on two rolling roads

Engine dynos are just as variable. Sweep rate alone on a water brake will change things.

Chris,

I doubt they do. It's not hard to figure out who's blustering. I think a lot of TR's end up around 180-185bhp. Most are also using the same tried and trued formula. Trap speeds usually show who has what.

-

Driving sure helps, but it's also what your competition has. For example, the vintage B-Sedan classes here (1.8L Datsun 510, 2L Alfa GTV), the front is turning 2:36-2:38's at Road America. Chris, your IMSA TR8 with its previous owner, did a 2:39. A 120hp TR would be lapped by those cars... It's also not going to beat a 150bhp Sprit or a 140hp Spridget, weighing 600lbs less.

175lb-ft isn't a lot for the engine size. I know of 2L engines of similar vintage, but from other country origin, making more than that, and with 2 valves.

There really is no secret. It's an airflow problem. You start with a program like this:http://maxracesoftware.com/PipeMaxPro400.htm

Figure out your power goals and where you want it to peak, it'll help you figure out how much air you need to move, and then work a cylinder head specialists and camshaft designers to get you there. If your guy can't, find someone new, likely you'll have to go outside the little Triumph / BMC cottage industry. Cylinder head specialists vary in their skill, but at minimum, they need to be working on benches that flow 28" H2O, ideally higher. Again, it's a balance between mass flow and velocity. Lobe designers - don't settle for anything recycled from 1968 and it's going to take over .600" at the valve (and you need to figure out how to make it live), most exhaust systems are lacking, more compression but not at the expense of good combustion, etc. It's all just good race engine building know-how.

-

175lb ft of torque at 5700rpm is possible with the TR4 engine to the rear wheels, but that's a real race engine (and not a hand grenade), but it's still nothing out of this world BMEP wise.

I usually figure 100hp / L is a good starting figure for a proper vintage race engine of any type (Spit, BMC A-Series, TR 4-6's, MGB's, etc.). Over that requires A LOT of work, but it's possible. The best A-Series here, are 108hp/L, and still pretty tractable, with SU's and stock valve sizes (rules required in SCCA Production competition). A great Spit engine is going to make 150bhp, or thereabouts.

Also, keep in mind dyno's vary. Peter Burgess uses a Dynocom which according to the internet, reads a chunk higher than a Dynojet which typically reads higher than a Mustang type.

-

The torque saying should be revised:

Producing the most torque at the highest amount of RPM wins races

-

I've seen a 5 port A-Series with modern development and fuel injection make 165bhp... 126 hp/L.

Efficiencies decrease with engine size, but I have no doubt with a proper modern development regime, over 260bhp is possible.

-

Good stuff, John. +1 to what happened at the end?

-

At the start? The grids are set side-by-side. Green flag is out, passing is allowed. Pole only gets inside track position for turn 1, we were qualified on pole (up to 8s/lap at one point) and pulled in early. The Lotus set a time a little faster on the last lap of the session. It didnt matter as we knew (and told him - very friendly guy) that the TR was going to go sailing by at the start. The Lotus played the start better on Sunday, but a fast in a straight line Datsun (~225bhp from a 2L 510 engine) ran up the inside and foiled his plans.

-

Hah. Rules are rules. Do you still have your TR4?

-

Hey Mick,

.040 on the 86mm, so 87mm is what everyone runs. I think most anyone serious is offsetting the head to at least some degree.

Standard stroke dimensions - all the serious racers are running ghost main billet cranks. Bearing sizes, etc. are all free.

-

Hey guys, he's shifting at 6500 (except the starts), but the shift light was creeping down. Makes power and will spin up to 7000, but well only do that in anger (and power typically isnt the problem).

Rules here in the States are based off old SCCA regs. So .040 overbore, no stroker cranks, no dry sumps, and no crank trigger ignition. Just about everything else is free and we can get 112 octane leaded race fuel here no problem, so compression ratios are higher than you see in Europe.

5spds are allowed in vehicles that came with overdrive stock, but has to be production based (internals are free). A close ratio dog box Triumph transmission with an overdrive would be just as fast, but less reliable.

Car has to weigh 2150lbs w/o driver. The Lotus is 1250lbs, but hes 150lbs over the rules allowed 1100lbs.

Pictures here: www.the71crowd.com

-

Thought you guys might enjoy this...

Saturday race:

Drying conditions. TR4 fast lap: 1:36.560, Lotus fast lap: 1:35.632

Sunday race:

Dry condtions. TR4 fast lap: 1:34:365 , Lotus fast lap: 1.34.175. Average speed ~86mph. Both turn their fastest lap on lap 4 (5:20 in)

In-car from the Lotus..

Enjoy!

-

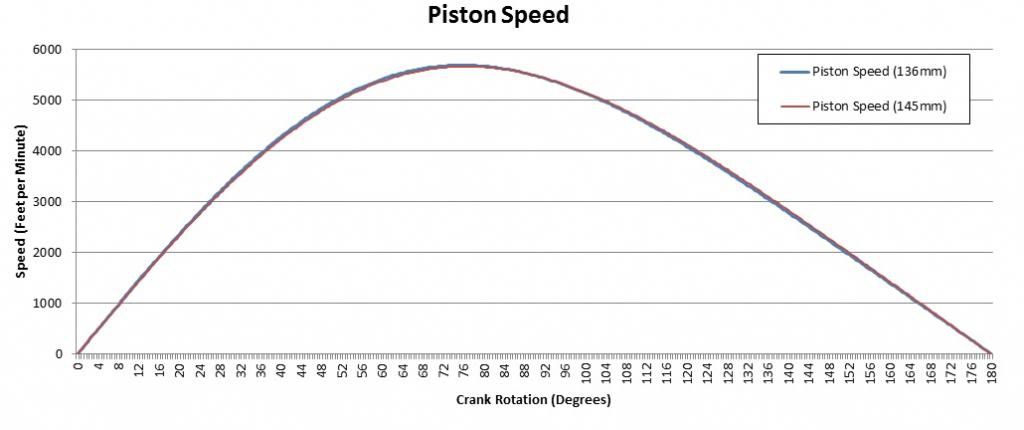

Longer connecting rods will reduce the mean piston speed, but just barely.

One can play with the stroke/rod game, but when you figure out what can be used at maximum (in relation to where to put the piston pin), you'll find there isn't that much difference.

The real gain comes in using a much lighter and stiffer piston. With the long strokes typical of the British lumps, anything you can to reduce rotating weight will mean longer life of the block itself. With the 4cyl TR engines, the block, for the very best engine builder, is becoming the Achilles heal and he's done everything to take weight out of the rotating assembly.

Here is an example I made years ago:

Same engine, 7200rpm peak. 136mm long connecting rod to a 145mm long connecting rod.

Peak piston speed (FPM):

136mm: 5685 FPM @ 76 degrees crank rotation.

145mm: 5661.2 FPM @ 76.5 degrees crank rotation

Here is the real reason why you put longer connecting rods in. This for a 1296cc Spitfire engine:

-

Oil pump:

Stock modified by Steve Yott, http://www.tonydrews.com/OilPump0001.pdf

Piston clearance:

Dependent on what type / manufacturer. A common forged piston will ever in the .003 - .0035 range. I can't comment on cast Pistons.

Valve springs:

Contingent on valve and retainer weight,how aggressive you are going to cam it and the rocker ratio, how much you're going to lift the valve. For the run of th mill street engine, get them from s source like here:http://www.aptfast.com/ShowItem/103426%20TRI%204%20Cylinder%20Double%20Valve%20Spring%20Set.aspx

Pushrods:

Trend, Manton, or Smith Bros in the US. You want them as strong as possible and to be steel.

Lifters:

Stock just ask the cam grinder about taper before you have them reground.

-

Likely different expansion rates. I do agree with the premise of filling the port as the TR ports are huge - at least at the inlet.Yes the builder had the head filled, yes it has to come out and be re-done, any suggestionsbonnwhy it may have lifted like that?

Graeme

Typically head porters will use epoxy like Splashzone or Devcon on aluminum heads. Sometimes you see them on iron drag race heads, especially in the NHRA Super Stock classes (stock head casting / port volume rule). Those guys will key the epoxy in with grooves cut into the port and the insertion of machine screws for it to grip on to. Even then however it requires to be ground out and reapplied after so often and methanol and other racing fuels will eat it if it is my sealed properly. See the attached.

On the iron heads you all see porters use metal tongues that are attached to a flange gasket.

Really the best way to do it is to weld the ports up however. This is probably aluminums biggest advantage when it comes to heads - the ease to modify.

Did he give you flow numbers? Cross sectional area numbers? I'd really think about starting over with it. I can't help with a UK source, but I definitely could give you some names in the States who will do a fantastic job on them.

-

I've seen those Ford lifters disentigrate like that too.

Keep in mind those Ford lifters are a smaller diameter than a stock Triumph lifter. If you're mixing and matching parts, it's not a good thing...

The best TR4 race engines are using stock diameter tool steel lifters on a custom billet steel cam core. That's almost a $1000 set-up. Obviously, you don't need that though

How is your valve retainer to guide clearance?

Not sure what spec valve springs Ken is selling.

Did your cylinder head guy fill in the floor? Looks like he used lead? If it's lifting, then that needs to come out.

TR4 engine compression test

in General TR Technical

Posted

Do you have a reference to what it was when the motor was first built and after it was broken in? Done cold?

A huge jump between the two would indicate ring seal, but who knows where you’re at relative to where it was assembled. A leakdown test would tell you more considering you don’t have a baseline to compare to.