-

Content Count

1,500 -

Joined

-

Last visited

Content Type

Profiles

Forums

Calendar

Posts posted by angelfj

-

-

Hi Frank.

Are you still making these tags?

If so how should I contact you to have one made?

Body No. 842442 I don't know the other number, & not possible to find out !

Bob.

yes, I am still making them. Send me a pm with your requirements and email and I will respond.

Frank

-

The weather this month has been unusually mild. it got up to 60F this monday, so I took the Grey Lady for her last run of the year.

Cheers,

Frank

-

When we were cleaning up the block, we could see the faint outline of the red/orange painted TR3. We took several photos and made measurements. Later when the block was painted we applied the TR3 as original. You can see it in the photo below although partially obscured by the exhaust manifold.

Cheers, Frank

-

Well done - loved it!

-

You never know what will show up at Duryea Day - Boyertown, PA - held every year on the Saturday preceding Labor Day.This TR3 was restored per factory build record and wears a beige exterior - the first I have ever seen!

The owner bought the car in 1968 for $75. It had been illegally parked and then towed by the city.

THE PROUD OWNER

VERY CLEAN ENGINE BAY (note lower bulkhead brass tag made by yours truly)

SAME INTERIOR COLOUR AS THE GREY LADY

ME CHATTING WITH THE OWNER (white cap)

-

Last Saturday we made our annual trek to Boyertown, PA for Duryea Day. We always seem to find unusual cars with unusual features. This year was no different. A car described by the owner as a TR2.5 pulled up along side our group and this turned out to be a very interesting car indeed!

The owner considers this car a TR2.5 because the body panels and a number of major components are a hodge-podge of TR2, TR3 and TR3A bits.

Also, his off side mirror and rear wheels are something I have never seen before.

See below.

The wheels include what at first looks like a trim ring (painted black) but upon close inspection these "rings" are in fact an integral part of the wheel. Any thoughts.

This mirror, with engraved or stamped TR logo, must be an after-market product, but I've never seen one. Have you?

.

-

USA spec cars may be another matter, our transatlantic correspondents can offer more experience on this score, I'm sure.

Nope! USA spec TR's are no different regarding engine bay paint colour. Always the same are body colour. So the only TR's that should have engine bays painted black are those that were painted black at the factory!

-

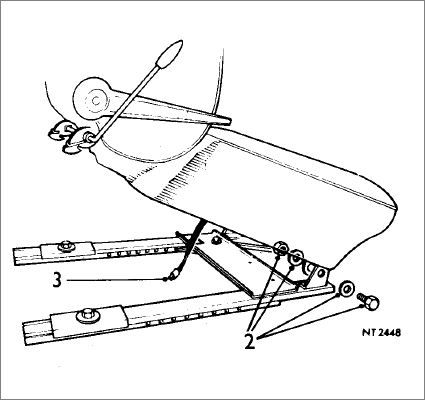

I finally have some time to devote to the 250. I had to remove the driver side seat recently and noticed (for the first time) that there are two holes at the attachment point. See drawing below from the TR6 manual which shows only one hole. Why does the TR250 provide two holes and which one is correct?

TR6

TR6 TR250

TR250 -

Best guess is that spare blocks were stocked for local rebuilding by Triumph dealers in America, and therefore never got numbered.

Yes, that would make sense!

-

Didn't the factory grind the original number away before fixing a plate to say the the engine was now a factory reconditioned unit?

Ian Cornish

Yes, I was about to ask the same and partially a reason for my original query. I came across a TR3A engine block with NO engine number - just ground smooth. I thought perhaps a reconditioned unit. Just the block mind you, no liners or anything else!

-

Looking for a photo of a factory reconditioned engine plate, in situ.

Cheers,

Frank

-

Thanks Graham! I try to learn something every day!

-

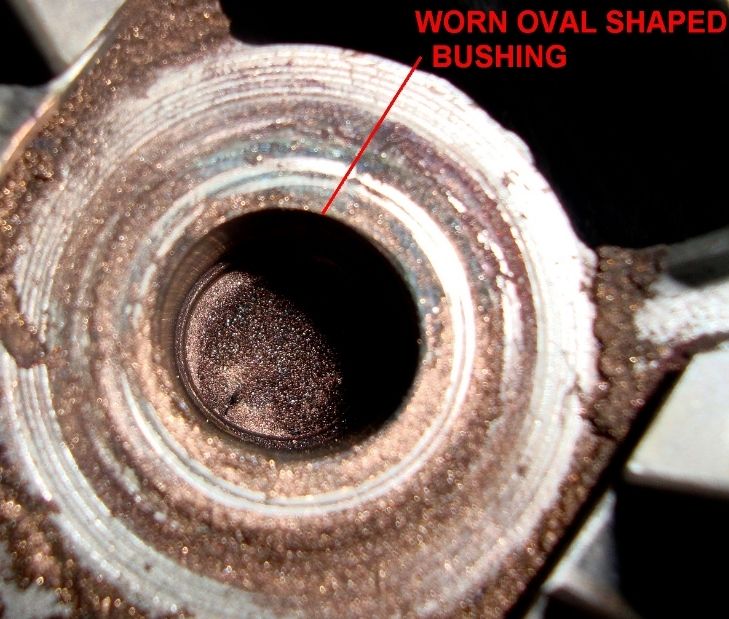

I do admit that the needle bearing decision was debated. One problem is that we had no idea of the armature shaft hardness at the bearing journals. Needles can be very rough on softer metals. Generally speaking, the proper approach would be to calculate the bearing PV and then match up the PV with suitable bearings.

-

I would have thought the reason for failure to charge given the wear in the rear bush would be the armature polling. This would add to the squeeling noise as well

Graham

Graham: I'm not familiar with the term, "armature polling". Can you explain? Thanks!

-

I had hoped not to have to return to this topic again. My last report had us in possession of new viton top hats which we installed and really had no problems until this past weekend. Sunday morning I started my usual cleanup ritual which I follow after each show. When I opened the garage door I immediately noticed the string smell of gas. With the bonnet up it was easy to see that the front carb had been leaking badly, just under the float bowl-to-carb bolt. The rear carb was dry. Scratch of the head??? Ah! Recalling that on friday we had to remove both air filters and disconnect the choke linkage in order to remove the bad dynamo and install the new one. It is very possible that we disturbed the front bowl causing the seal to fail. But, come on, must these buggers be so sensitive. So, I have closed my in-line fuel cut off and will not be running the engine until I am satisfied with a better fix. Just for the record we put about 1500 miles on the car without any fuel leaks.

Have there been any new innovations since I started this thread in October of last year?

FOLLOW UP

We eventually installed new top hat seals from Moss USA. They now have almost 2500 miles on and haven't leaked a drop!

Cheers, Frank

-

Nice work on the dynamo by the way, but looks expensive!

Rgds

rod

Yes, if you don't have access to a lathe and the skills needed, it could be expensive. The parts are cheap, approx. $10 each for the front and rear bearings.

Cheers, Frank

-

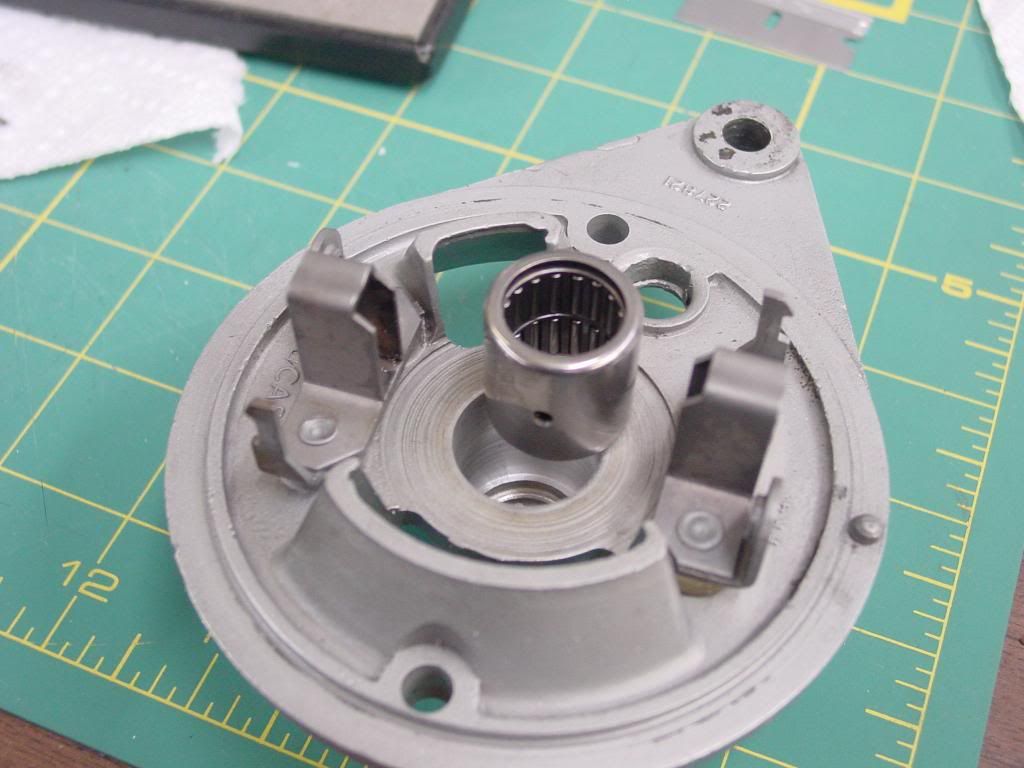

Photos showing how we did this.

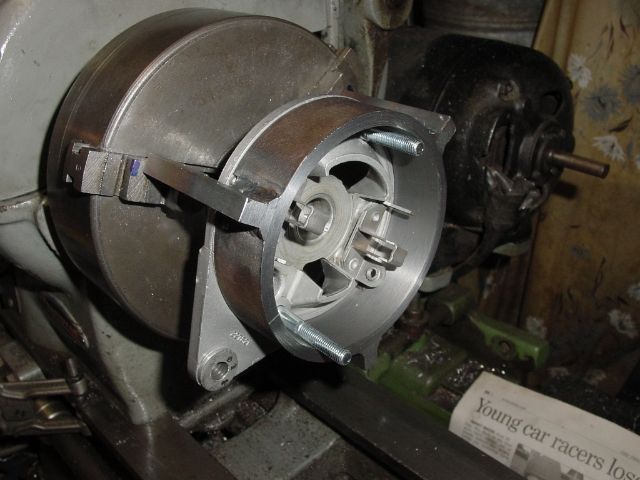

The old bronze bushing had to be removed to install the new needle bearing. This required a special fixture to hold the rear dynamo plate in the lathe chuck.

Rear dynamo plate in fixture /lathe using boring bar to remove old bushing.

Needle bearing reading for pressing into rear plate.

New needle bearing in place.

-

I am in the process of restoring my '54 TR2, it's been off the road since the late '60s.

My car was originally painted Signal Red but all the original trim and seat coverings had been replaced with Black from a TR3a. In researching the color combinations possible, I have found that my original trim colors could have been: Brown, Red or Stone. But I can't find exactly what Stone looked like. And how Brown is the original Brown? None of my reference books label any interior TR2 pictures as having Stone or Brown for the trim.

Does anyone know of any links that show what this color actually looks like?

Thanks for any help in sorting this out......

John

John: Hope you are aware that there's help on this side of the pond. For the early side screen cars I recommend TRA.

For the forum goto: http://triumphregister.lefora.com/

For the main website goto: http://www.triumphregister.com/

Cheers, Frank

-

Just returned from the Triumph Register of America Annual Meet in Western , Kentucky. Yes, I drove her - all 1900 miles. She ran like a scalded dog - no problems. No generator issues and I ran day and night with headlamps lit.

Question: Our interstate highways allow 70 mph. So, there was very spirited driving with occasional bursts to 80+. At these speeds I was not able keep the soft top snaps fastened. The middle one and often the two on either side would loosen. Occasional rain spray was refreshing, but not requested. Of course the top, snaps and pegs are all new. Is there a trick to the proper use of these Tenax soft top fasteners?

Cheers,

Frank

-

The dynamo has been completely rebuilt.

We replaced the armature, field coils, front and rear bearings, basically a new dynamo. We did all of this work to retain the correct and original case with proper date code.

some notes:

The armature available from Moss USA is metric. It has a key way narrower than the pulley and fan. This required a special key which had to be milled. In addition, the nut which secures the fan and pulley is metric, so the original nut will not fit. It would have been helpful for Moss to indicate the differences between this replacement armature and the original Lucas unit.

The front open cage ball bearing was replaced with a sealed, lifetime lubricated unit, model 6201, German made (INA). http://www.mcmaster.com/#6201-ball-bearings/=n4pzny

The rear oilite bronze bushing was replaced with a needle bearing. (model number later). The needle bearing has a lubrication grove. We were careful to retain the original felt which we will keep oiled and it should feed lubrication to the new bearing.

The new dynamo spins very freely with no noticeable radial or lateral deviation.

I am currently using an original Lucas, electromechanical control box. I believe there is an intermittent fault in the solid state unit I had been using, perhaps one of the electronic components is breaking down.

For long trips I intend to travel with a spare dynamo and control box.

Additional detail later as I gain experience.

Cheers,

Frank

-

You know, I really get ****** off when suppliers do this.

We recently bought a replacement armature from Moss USA, part number 162-900, for $42.95. I was very impressed with the quality of this piece and the price seemed fair.

BUT, here we are in the 11th hour trying to fit the new dynamo and discovered, to our astonishment that the keyway/key in the new armature shaft is smaller than that in the original fan/pulley!

AND

The original nut does not fit the new armature shaft. I bet its metric.

This is going to be a very difficult fix.

OK - what really frosts me to no end is that there is/was no indication in the parts list or in the box that this part was in any way different from the original.

So, if you plan an armature replacement, a word to the wise!!!

Gee I'm ******!!!

-

Thank you for all of these good suggestions. I'll report on exactly what we find soon, but to answer a few questions that I am able:

There is no current being produced by the dynamo, thus the red light.

I am using the cogged version of the wide belt.

From what I can gather from the workshop manual, our belt tension seems normal.

Pulley alignment seems to be very good.

The front ball bearing and rear bush are original.

I did find something interesting on a British website. This guy rebuilt a Lucas C40 dynamo and substituted a ball bearing for the normal rear bronze bush. We may try this. Read about it here: http://landcrabs.proboards.com/index.cgi?board=tech&action=display&thread=22

-

This is not supposed to happen!

Go here for background:http://www.tr-register.co.uk/forums/index.php?/topic/40709-complete-charging-system-failure/?hl=%20generator%20%20dynamo%20%20failure

Very busy weekend had us at two shows. I said I would drive this car and I'm trying my best to do so.

Up until this weekend, the new (rebuilt) dynamo had been in service for less than 100 miles. So, driving back from Maryland yesterday with approximately 100 miles to go, the ignition lamp went red. Having been through this before, I immediately reduced the electrical load to only the essentials which meant off with the headlights. I always drive night and day with the headlights on and these had to be turned off. The resulting electrical load , ignition, overdrive solenoid, fuel gauge was perhaps 5 amps total load on the battery - more than enough to provide high voltage for sparking plugs for the drive home.

Got home , showered and went to bed. I was tired of that red light staring at me. I was also very pissed off. The timing is real bad since the Triumph Register of America convention is next week in Kentucky, an 1800 mile round trip. I must have a reliable car.

Like I said, I've been through this before. This morning I did some quick tests, but its obvious from the screeching sound that the dynamo is making that a failure similar to the first one has occurred. Oh, and we did check and lubricate the replacement dynamo. So, the only thing that I am aware of is a too tight belt, and I have to tell you the belt tension is per the book.

You may be thinking this, but no, thank you very much, I am not interested in an alternator. I know several sidescreen TR owners who together must have a few hundred thousand miles on their original dynamos. I didn't get 400 miles on this one!

Am I missing something?

Disgruntled, Frank

-

I had hoped not to have to return to this topic again. My last report had us in possession of new viton top hats which we installed and really had no problems until this past weekend. Sunday morning I started my usual cleanup ritual which I follow after each show. When I opened the garage door I immediately noticed the string smell of gas. With the bonnet up it was easy to see that the front carb had been leaking badly, just under the float bowl-to-carb bolt. The rear carb was dry. Scratch of the head??? Ah! Recalling that on friday we had to remove both air filters and disconnect the choke linkage in order to remove the bad dynamo and install the new one. It is very possible that we disturbed the front bowl causing the seal to fail. But, come on, must these buggers be so sensitive. So, I have closed my in-line fuel cut off and will not be running the engine until I am satisfied with a better fix. Just for the record we put about 1500 miles on the car without any fuel leaks.

Have there been any new innovations since I started this thread in October of last year?

TR Engines Freeze Protection

in TR2/3/3A/3B Forum

Posted

Hey guys!

It's been a brutally cold winter here in the N.E. USA. My TR's are stored in an unheated detached garage. My 3A and 250 engine cooling systems are currently filled with a water/coolant mix good for approximately zero degrees F. I got real concerned when the temperature dropped below zero a couple of weeks ago, so I set up some 1000 watt shop lamps under each oil sump. Then I covered the tops of the engines with heavy cloth pads like those the home (re)movers use. I think I came through this crisis unscathed, but I'm looking for a more practical approach for next season. In the extreme northern USA, car owners sometimes use engine block heaters and/or oil dip-stick (immersion) heaters. These devices have built in thermostats that are supposed to maintain the temperature above freezing. The block heaters are designed to fit in place of one of the freeze plugs. They have to be ordered by spec to fit a particular engine. The dip-stick immersion heaters are generic. Both devices are designed to plug into a standard AC (mains) outlet.

I was hoping that one of our members who lives in extreme northern climes could share their methods of maintaining TR's during very cold weather. Is anyone aware of an engine block heater that could be fitted to my TR engines?

Regards, Frank

p.s. heating the garage is not in the budget!![:P]()